Welcome, Saturday , Jul , 05 , 2025 | 23:06 IST

Welcome, Saturday , Jul , 05 , 2025 | 23:06 IST

IPR Status: Copyright

Status of commercialization: Industry Partner: • M/s AMBICA INDUSTRIES, Isanpur, Ahmedabad-382443, Gujarat • M/s Shubham Corporation, Ahmedabad-382425, Gujarat

Techno-economic: Technology Transfer Fee: Rs.10.0 Lakh plus GST@18% for Micro & Small Enterprise of MSME and Rs.15 Lakh plus GST@18% for Medium Enterprise of MSME & Large Co.

Technology package: Complete Manufacturing Drawings & Technology Know-how with Operation Manual, List of Bought Out Materials with Sources etc.

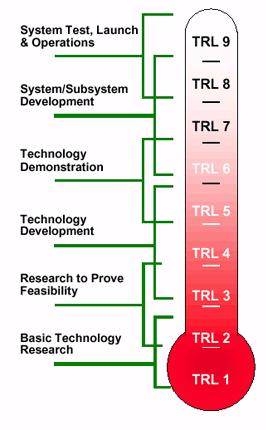

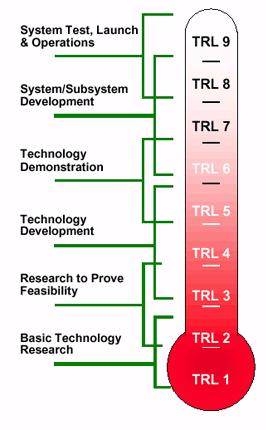

TRL: TRL 6

IPR Status: Patent

Level/Skill of Department: Prototype developed at actual scale and demonstrated in actual field environment at multiple occasions 80% indigenous (Motor controller & LiFePO4 Cells are imported)

Major raw materials to be utilized : Transmission assembly, Structural frames and panels, electronic controls, circuit breakers, converters, lights, horn, switches, connectors, cables, SOC display, electric motor, battery pack, cells for battery stack and motor controller.

Status of commercialization: Industry Partners (Licensee): M/s K.N.Biosciences India Pvt.Ltd., Bachupally Road, Industrial Area, Ameenpur, Miyapur, Hyderabad-502325, Telangana

Techno-economic: Return of Investment : Within 2-3 years

Technology package: Complete Manufacturing Drawings & Technology Know-how with Operation Manual, List of Bought Out Materials with Sources etc.

TRL: TRL 6

IPR Status: Patent

TRL: TRL 6

IPR Status: Patent

Major raw materials to be utilized : The details of the raw materials and machineries required are part of the Technology Transfer Document.

Status of commercialization: Technology/Know-How was transferred to Complete: 1. M/s Ecosafe Zero Waste Solutions (P) Ltd., Panch Shiv Mandir, Housing Board Colony, Patna-800020, Bihar 2. M/s Joint Enterprise Engg.Co., Durgapur Industrial Estate, JP Avenue, Durgapur-713212, WB

Techno-economic: Technology Transfer Fee: Rs.12.0 Lakh plus GST@18% for Micro & Small Enterprise Rs.16.0 Lakh plus 18% GST for Medium Enterprise & Large Scale Co. Manufacturing Cost: Rs.40-45 lakhs (approx..)

Technology package: Complete Manufacturing Drawings & Technology Know-how with Operation Manual, List of Bought Out Materials with Sources etc.

TRL: TRL 6

IPR Status: Patent

Level/Skill of Department: • Designed & developed the prototype in different categories of MCV & demonstrated to MHA Committee. • Its QR/TD has been recommended by MHA committee and subsequently approved by DG, CRPF in March, 2022

Major raw materials to be utilized : Petrol and tear gas generating solution tank, SS Pipe, pipe clamps, nozzles, headers, solenoid, valves, switch box and electrical wiring, pipe network, steel structure

Status of commercialization: Technology was transferred to M/s Himatsingka Agencies Pvt.Ltd., Bhagalpur Road, Dumka-814101, Jharkhand

Techno-economic: Technology Transfer Fee: Rs.5.0 Lakh excl. GST

Technology package: Complete Manufacturing Drawings & Technology Know-how with Operation Manual, List of Bought Out Materials with Sources etc.

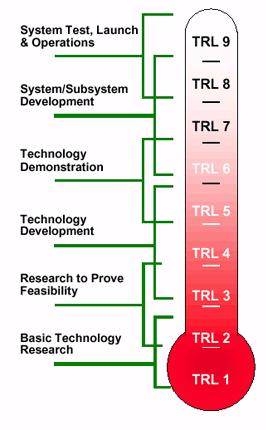

TRL: TRL 7

IPR Status: Patent

Level/Skill of Department: • Designed & developed the prototype in different categories of MCV & demonstrated to MHA Committee. • Its QR/TD has been recommended by MHA committee and subsequently approved by DG, CRPF in March, 2022

Major raw materials to be utilized : Blowers, duct line, installation of mechanical system, electrical connections, differential pressure based controller, variable frequency drive controller, 08 Nos. of discharge ports etc.

Status of commercialization: Technology was transferred to M/s Himatsingka Agencies Pvt.Ltd., Bhagalpur Road, Dumka-814101, Jharkhand

Techno-economic: Technology Transfer Fee: Rs.7.0 Lakh excl.GST

Technology package: Complete Manufacturing Drawings & Technology Know-how with Operation Manual, List of Bought Out Materials with Sources etc.

TRL: TRL 7

IPR Status: Patent

Level/Skill of Department: • Designed & developed the prototype in different categories of MCV & demonstrated to MHA Committee. • Its QR/TD has been recommended by MHA committee and subsequently approved by DG, CRPF in March, 2022

Major raw materials to be utilized : Manual, valves, pump, Bifurcated water tank, SS Pipe, BSP Pipe Tee, Nipples, spray nozzle, flexible hose, pipe clamp, groove pulley, V belt, switch box and electrical wiring, steel structure

Status of commercialization: Technology was transferred to M/s Himatsingka Agencies Pvt.Ltd., Bhagalpur Road, Dumka-814101, Jharkhand

Techno-economic: Technology Transfer Fee: Rs.8.0 Lakh excl.GST

TRL: TRL 7

IPR Status: Copyright

Level/Skill of Department: • Designed & developed the prototype in different categories of MCV and demonstrated to MHA Committee. • Its QR/TD has been recommended by MHA committee and subsequently approved by DG, CRPF in March, 2022

Major raw materials to be utilized : PoE Switch, Accessories eg. Cables, Switch etc.

Status of commercialization: Technology has been transferred to M/s Himatsingka Agencies Pvt.Ltd., Bhagalpur Road, Dumka-814101, Jharkhand

Techno-economic: Technology Transfer Fee: Rs.8.0 Lakh excl.GST

Technology package: Complete Manufacturing Drawings & Technology Know-how with Operation Manual, List of Bought Out Materials with Sources etc.

TRL: TRL 7

IPR Status: Copyright

Level/Skill of Department: • Designed & developed the prototype in different categories of MCV & demonstrated to MHA Committee. • Its QR/TD has been recommended by MHA committee and subsequently approved by DG, CRPF in March, 2022

Major raw materials to be utilized : 18” Display, Accessories eg. Switches, wire, mcp, keyboard, mouse etc.

Status of commercialization: Technology has been transferred to M/s Himatsingka Agencies Pvt.Ltd., Bhagalpur Road, Dumka-814101, Jharkhand

Techno-economic: Technology Transfer Fee: Rs.7.0 Lakh excl.GST

Technology package: Complete Manufacturing Drawings & Technology Know-how with Operation Manual, List of Bought Out Materials with Sources etc.

TRL: TRL 7

IPR Status: Design Registration

Level/Skill of Department: • Designed & developed the prototype in different categories of MCV. • Its QR/TD has been recommended by MHA committee and subsequently approved by DG, CRPF in March, 2022

Major raw materials to be utilized : Steel structure, hydraulic cylinder etc.

Status of commercialization: Technology has been transferred to M/s Himatsingka Agencies Pvt.Ltd., Bhagalpur Road, Dumka-814101, Jharkhand

Techno-economic: Technology Transfer Fee: Rs.3 Lakh excl.GST Return of Investment : Within 2-3 years

Technology package: Complete Manufacturing Drawings & Technology Know-how with Operation Manual, List of Bought Out Materials with Sources etc.

TRL: TRL 7