Bearings (Foil & Magnetic):

One of the thrust research areas of SE&T is to develop bearings which reduces friction in machine elements; particularly macro/micro machine components where the ratio of area to volume is high, hence results friction in higher side. To overcome this non contact type bearings have been the focus area of research. Among these category of bearing, magnetic bearing and foil bearing are one of the important bearings. With the support of XII five year plan, extensive work towards the development of magnetic and foil bearings was carried out. Comprehensive knowledge on such bearings is obtained with theoretical and experimental studies.

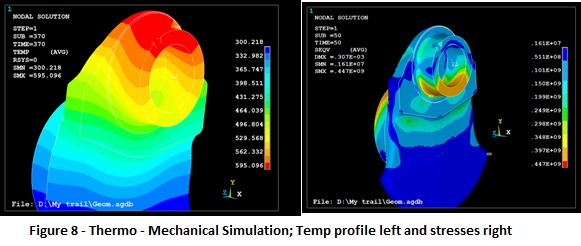

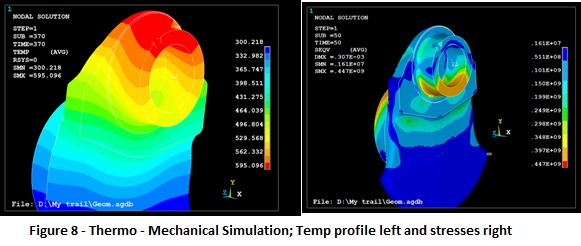

In magnetic bearings, one new type of passive magnetic bearing, called electro-dynamic bearing has been introduced. The working principle of the said bearing is that, once the electrical conducting rotor rotates in a magnetic field created by stator passive magnets, the eddy currents is induced in the rotating conductor. This induced current will produce a magnetic field opposite to the existing magnetic field and produce a repulsive force among these existing and generated magnetic field as shown in Figure 1. One of main advantage of this bearing is to get friction less operation without using complex control algorithm used in active magnetic bearing.

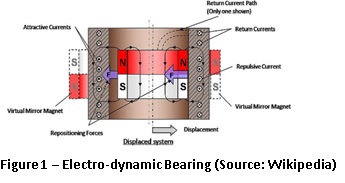

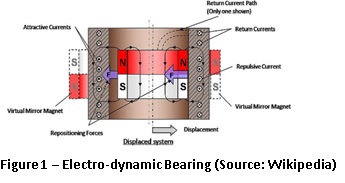

Another area of bearings where this group was successful in developing is foil bearing for high speed applications. Foil bearing which has been designed and developed at CSIR-CMERI is depicted in Figure 2 where solid inner face of air bearing is embedded with metal foils which give the cushioning effect to the rotor as well as increase stability of the rotor by allowing the bearing to operate at higher eccentricity ratio. A set up has been made to test the foil bearing and it was noticed that the bearing can run at a speed of 30,000 rpm. The potential utility of this bearing is in the turbomachinery area like air cycle machine used in environmental control system in aircraft, cryogenic turbo compressor, gas turbine engine etc. With the gained expertise in the foil journal bearing steps are being made to design and develop a thrust bearing of such kind.

Theoretical Analysis:

Several theoretical analyses are being carried in this research laboratory using commercial software's like ANSYS, FLUENT, ABAQUS etc. These analyses are used to validate the experimental findings. A few among them are:

Simulation of two-phase flow (for ink-jet printing):

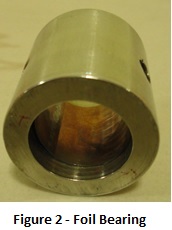

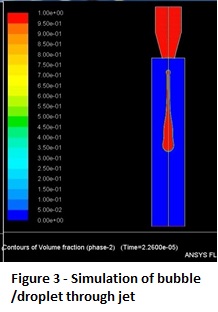

A CFD (Computational Fluid Dynamics) simulation has been carried out to study the behaviour of droplet under various operating conditions. From CFD simulation of two phase flow, one can investigate motion of the boundary of the interface between the liquid phase and gas phase, pinch-off of a droplet, formation of satellites, the effect of nozzle geometry on ink ejection size and motion, associated scaling laws are possible. One such simulation carried in FLUENT was depicted in Figure 3.

Further detailed study from the simulation can discover/verify different various regime of bubble formation depending upon the size and charge, time evolution of a droplet under moderate and strong electric field. Such studies can elaborate those features which experiments can not reveal. Researchers have determined the distribution of the electric field on the meniscus that forms at the tip of the nozzle and different modes of pulsation as a function of time. Slight modification of e-jet printing, spatial distribution and density of surface charges can also be predicted.

Further detailed study from the simulation can discover/verify different various regime of bubble formation depending upon the size and charge, time evolution of a droplet under moderate and strong electric field. Such studies can elaborate those features which experiments can not reveal. Researchers have determined the distribution of the electric field on the meniscus that forms at the tip of the nozzle and different modes of pulsation as a function of time. Slight modification of e-jet printing, spatial distribution and density of surface charges can also be predicted.

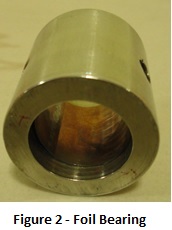

Welding Simulation:

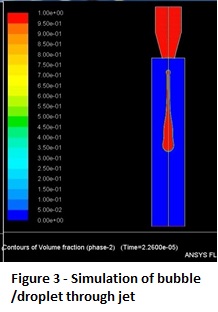

Welding is one of the major manufacturing operations carried out to join materials of either similar or dissimilar type. A side effect accompanying the welding operation is the generation of residual stresses, which are in general known to affect the fatigue life of the components. An attempt has been made to simulate the welding process using double ellipsoidal heat source (DEHS) model in ANSYS environment. It is observed that good penetration of heat source can be used by using this model. Since the heat generated by material plastic deformation is orders of magnitude less than the heat generated by moving heat source, sequential thermal and mechanical analysis has been carried out to realize the residual stresses. The temperature profile and corresponding residual stresses profile is presented below.

Research Head:

Real name:

Harish Hirani (1460)

Email

- Plaintext email only

- No

History

- Member for

- 9 years 7 months

77th Republic Day Celebration at CSIR-CMERI

77th Republic Day Celebration at CSIR-CMERI  CSIR-CMERI proudly participated in the “Radiant 2.0 Jharkhand Mega Exhibition” held from 29th to 31st January 2026

CSIR-CMERI proudly participated in the “Radiant 2.0 Jharkhand Mega Exhibition” held from 29th to 31st January 2026  Collaborating for a stronger future

Collaborating for a stronger future  CSIR–CMERI Smart Village Outreach at Kusunpur, Odisha

CSIR–CMERI Smart Village Outreach at Kusunpur, Odisha Smart Farm Technologies

Further detailed study from the simulation can discover/verify different various regime of bubble formation depending upon the size and charge, time evolution of a droplet under moderate and strong electric field. Such studies can elaborate those features which experiments can not reveal. Researchers have determined the distribution of the electric field on the meniscus that forms at the tip of the nozzle and different modes of pulsation as a function of time. Slight modification of e-jet printing, spatial distribution and density of surface charges can also be predicted.

Further detailed study from the simulation can discover/verify different various regime of bubble formation depending upon the size and charge, time evolution of a droplet under moderate and strong electric field. Such studies can elaborate those features which experiments can not reveal. Researchers have determined the distribution of the electric field on the meniscus that forms at the tip of the nozzle and different modes of pulsation as a function of time. Slight modification of e-jet printing, spatial distribution and density of surface charges can also be predicted.